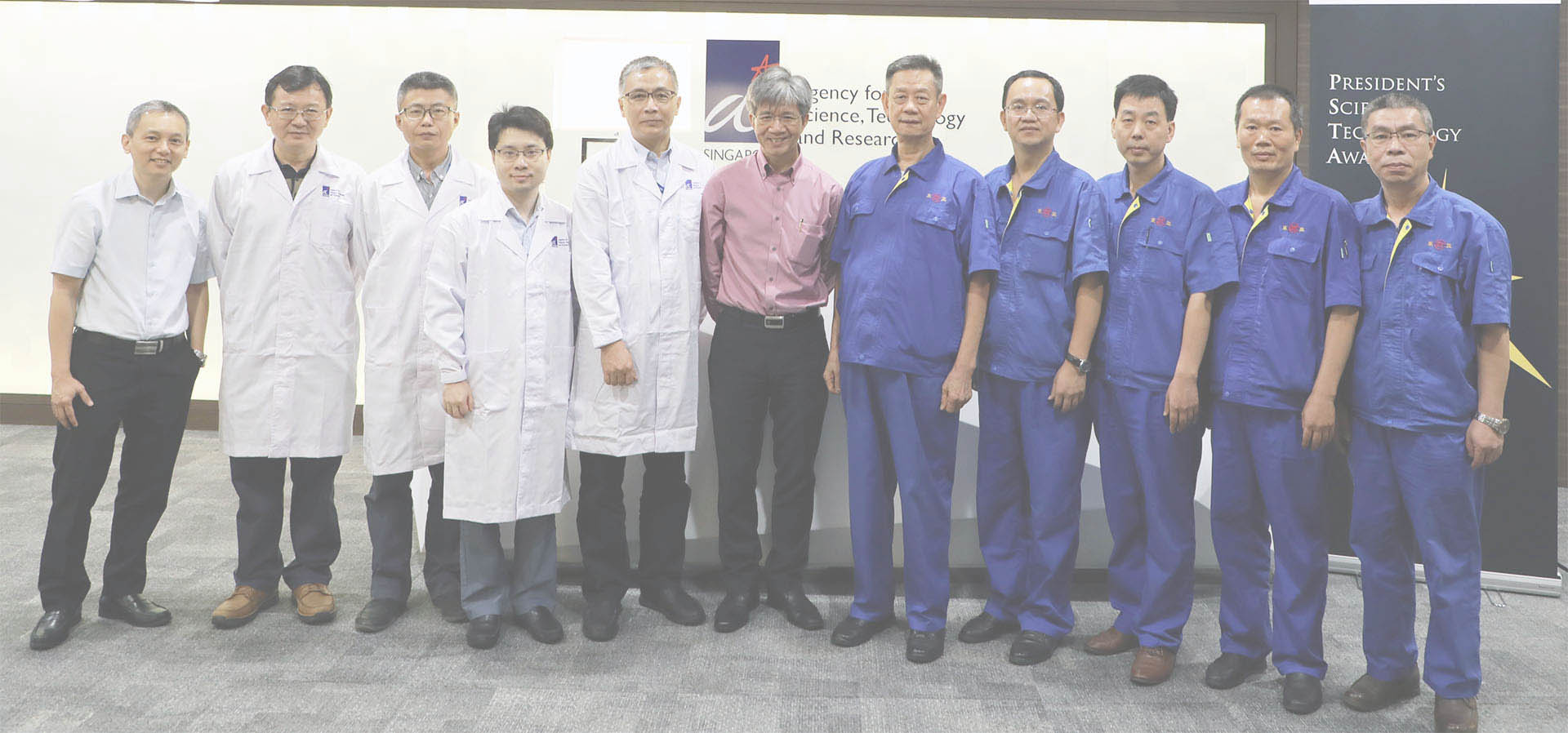

Equipment: the Via Qontor confocal micro Raman spectrometer of Reni shah from UK. can be used to estimate the relative content of sp3 and sp2 in DLC.

Equipment: X-ray photoelectron spectrometer from American Thermo Fisher Scientific. can be used for quantitative analysis of the relative content of sp3 and sp2 in DLC.

Equipment: SEM/energy disperse spectroscopy of FEI Nanolab, Netherlands EDX/FIB scanning electron microscope, which can be used to identify the surface structure of samples.The distribution of the elements in the microcosmic region of the material was qualitatively and quantitatively analyzed by energy spectrometer and electron microscope.The combined application of focused ion beam and electron microscope is an effective method for studying DLC thin films.SEM-FIB can study the tribological and wear properties and mechanical properties of DLC films from a microscopic perspective.

Equipment:Bruker atomic force microscope. It can be used to observe the surface morphology of DLC film. By studying the surface topography, the surface roughness of the film can be calculated, and the nucleation and growth mechanism of DLC film can also be studied.

Equipment: Swiss CSM high temperature friction and wear tester. (High Temperature Tribometer)is mainly used to study the friction coefficient and life of DLC coatings.

Equipment: Swiss CSM Nano Tribometer. The experimental parameters (relative speed, contact pressure, test time, test environment, etc.) are fully measured under with/without lubricant condition, tribological test that simulates the actual service conditions of materials.

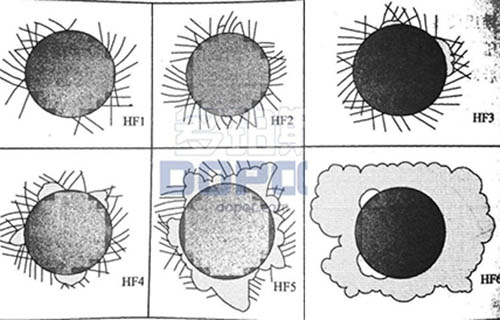

Equipment: British INDENTEC Roche hardness tester. Roche indentation test is used to evaluate the adhesion of thin films: The indentation test is performed on a Rockwell hardness tester. Different test methods are used for different substrates of different materials.

The figure shows the reference figure of edge crack of indentation, numbered HF1~HF6, form good to bad. By magnifying and observing the coating condition of the trace edge with the projector and comparing with the crack determination standard, the degree of coating adhesion was determined.