Our company specializes in the production of various types of piston rings and intelligent, high-precision equipment, providing high-quality products and services.

1.Intelligent High-precision Equipment

Automatic Fine Grinding Machine

High Strength Metal Cold Extrusion Molding Machine

Intelligent DLC Vacuum Coating Machine

2.Various Types of Piston Rings

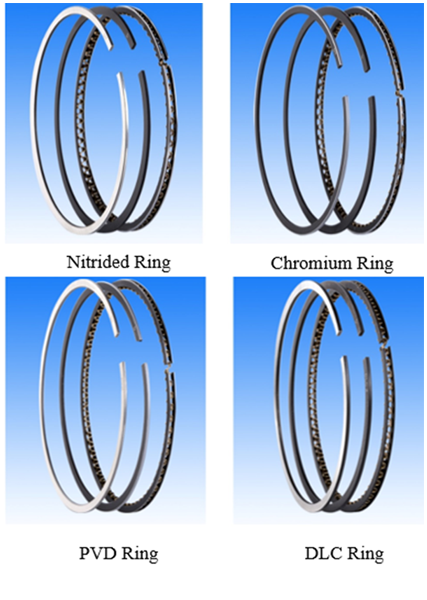

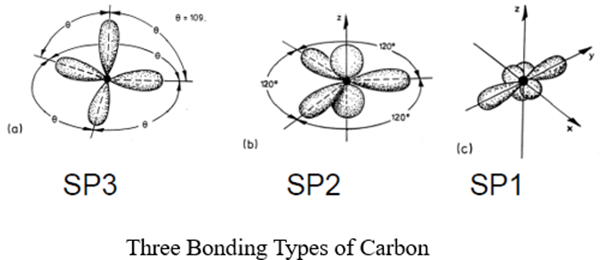

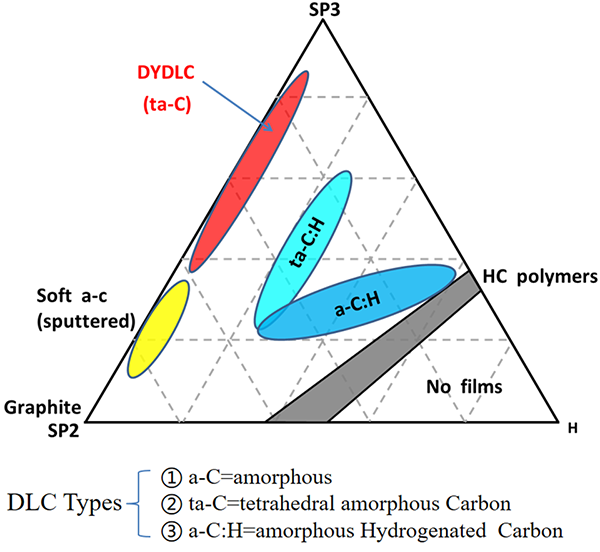

DLC is short for Diamond-Like-Carbon.

DLC is a kind of amorphous film composed of carbon elements, containing diamond bond sp3 and graphite bond sp2; has diamond similar performances: high hardness, good corrosion resistance; At the same time, it has the characteristics of graphite with very low friction coefficient.

DLC is short for Diamond-Like-Carbon.

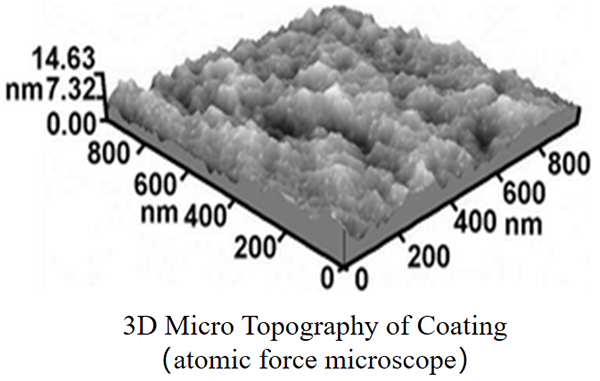

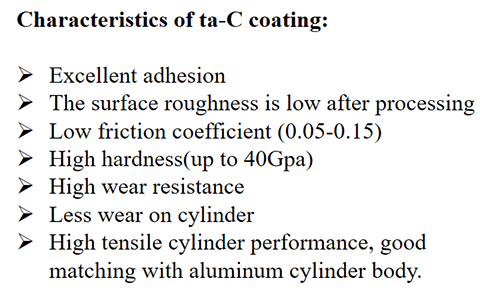

DY DLC is Ta-C coating, using magnetic filter cathode vacuum arc deposition technology, is the world’s most advanced piston ring surface technology.

Ta-C coating technology can be used for surface treatment of many friction parts of automobiles and motorcycles, such as automobile transmission system, engine main motion system, engine fuel system, engine valve system, etc.

① With ta-C coating on piston ring, the friction loss of compression ring will reduce by 12% and oil ring 6%. Scuffing resistance life increased by 635%.

② With ta-C coating on valve tappet, friction loss between CAM and tappet will reduce by 40%.

Investment Plan of DLC Equipment

① At present, DLC coating has been used in piston pin, valve tappet, piston ring and other engine parts.

② Motorcycles in China have adopted DLC piston rings since 2017, and the piston rings of automobiles have been put into mass production in 2019 after more than a year of test and evaluation.

③ DLC treatment rings will be a development trend in the next 5 years and will become the main piston ring coating to replace PVD.

④ DLC treatment is a coating process in the vacuum state, is environment-friendly , now the country is increasingly strict on environmental protection, DLC surface treatment replacing chrome plating will be an inevitable trend.

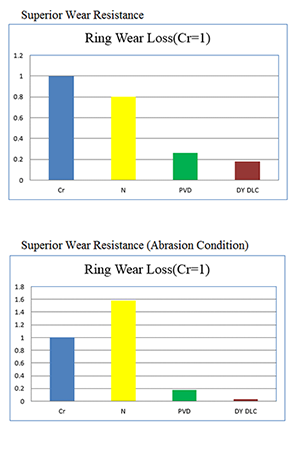

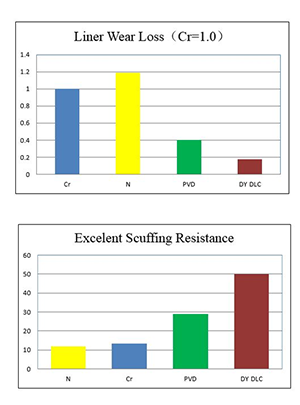

Wear and Scuffing Resistance

Under rapid friction and wear conditions, the wear resistance of DLC is over 25 % higher than other surface treatments.

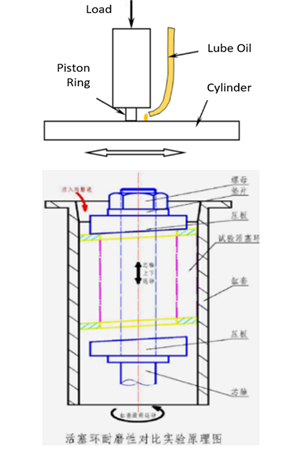

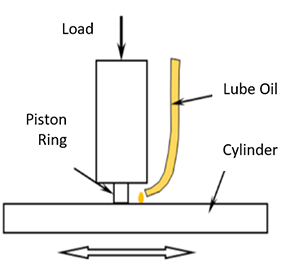

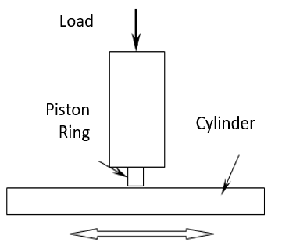

Using honing machine to imitate reciprocating motion of piston ring in engine cylinder, adding lubrication oil containing hard abrasive during motion, then measuring wear loss.

In case of abrasion condition, the wear resistance is about 8 times better than PVD.

Wear and Scuffing Resistance

● Less wear on cylinder

● Higher scuffing resistance against cylinder

● Better match with aluminum cylinder

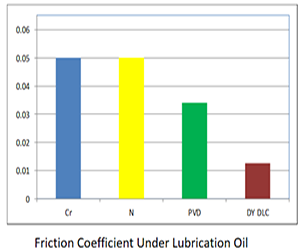

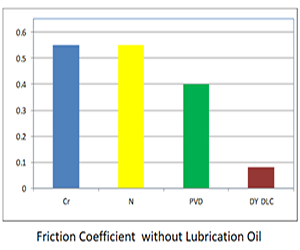

Friction Coefficient

Friction coefficient of DLC is significantly lower than other surface treatments under the condition of lubrication oil.

Dry friction coefficient of DLC under oil-free state has a more obvious advantage than other surface treatments.

Market Application

Three-Wheeler

CUB / Motorcycle / Scooter / Air compressor

General Purpose Engine Parts